RENT

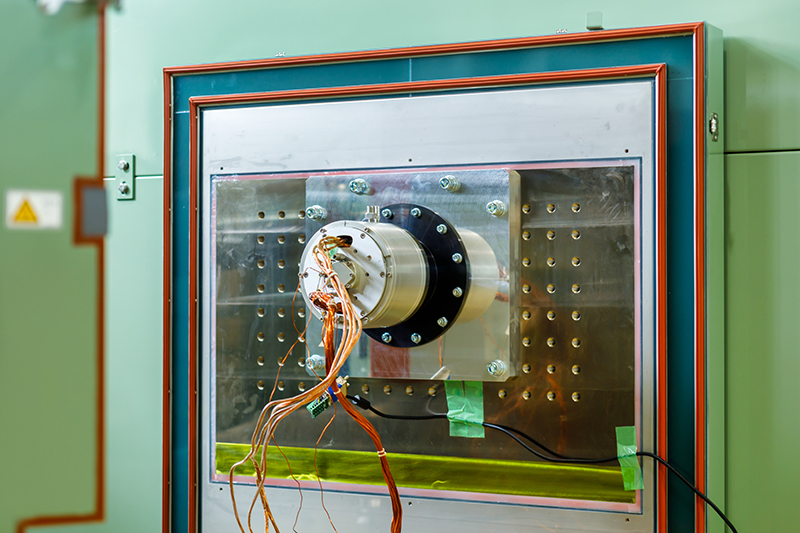

Motor Characteristic Evaluation System

You can use the motor characteristic evaluation system (manufactured by SINFONIA TECHNOLOGY Co., Ltd.), which is located in the former gymnasium.

This is one of the largest motor benches in Japan, with a maximum testing capacity of 400 kW and a maximum speed of up to 20,000 r/min.

The specifications of this device are shown in the attached PDF and the following table:

Table of Motor Bench Specifications

Dynamometer

| Capacity | Continuous rating:400kW |

|---|---|

| Rotation speed | 5,457 r/min (base) / 20,000 r/min (max) |

| Torque | Continuous rating:drive 700 Nm / absorption 700 Nm (within base rotation speed) Overload:120% for 1 minute (below base rotation speed, 10% ED) |

| Moment of inertia | Dynamo alone:0.295 kg m2 |

| Speed control range | Control range:0–20,000 r/min Settling accuracy:±0.02% FS in the range of 40–20,000 r/min |

| Torque control accuracy | Control range:0–700 Nm Setting accuracy: ±0.3 FS in the range of 14-700 Nm +torque detector accuracy (±0.2% FS) |

| Torque meter | Rated 1000 Nm(model HBM T40B) |

DC power supply (battery simulator)

| Capacity | 500kW |

|---|---|

| Voltage control | Control range:50–1,080 V Setting resolution:increments of 0.1 V Control accuracy:within ±0.1% of setpoint + 0.2 V (constant load, 200 times average evaluation) |

| Current control | Control range:-1000~+1000 A *If current limiting is activated, the output voltage is automatically adjusted so that the current does not exceed the preset value. |

In general, use cases include:

- Characterization of advanced motors and generators

- Various tests of motor-driven load (durability tests, environmental resistance tests, reliability tests, etc.)

- Verification tests of small/large systems by connecting the motor bench to the power grid installed in the gymnasium (in combination with the Copper Pheasant below)

For considerations and consultation regarding uses other than those listed above, as well as usage fees, please contact us.

Copper Pheasant

We have utilized a space in the former gymnasium corresponding to an actual size on aircraft (single-aisle aircraft), and have installed supporting members (cable racks) mimicked for the aircraft’s fuselage (see figure below). Aircraft system verification tests can be demonstrated by setting power cables and/or bus bars, motors, generators, and loads connected with them. The rig can be used as a test section for system verifications incorporated with developed samples (motors, generators, load, etc.) brought in by users.

For considerations and consultation regarding uses other than those listed above, as well as usage fees, please contact us.